一、MM32SPIN060G简介

使用高性能的 Arm® Cortex-M0 为内核的 32 位微控制器,最高工作频率可达 48MHz,内置高速存储器,丰富的 I/O 端口和多种外设。

- 16KB Flash,2KB SRAM

- 包含 12 位的 ADC,采样速度高达 1 Msps

- 2 个通用定时器、1 个针对电机控制的 PWM 高级定时器

- 1 个 I2C 接口、 2 个 UART 接口

- 针对电机应用内置 2 个运放

- 预驱工作电压高达 36V

- 工作温度范围(环境温度)-40℃ - 105℃

- 提供 TSSOP28,QFN28 封装

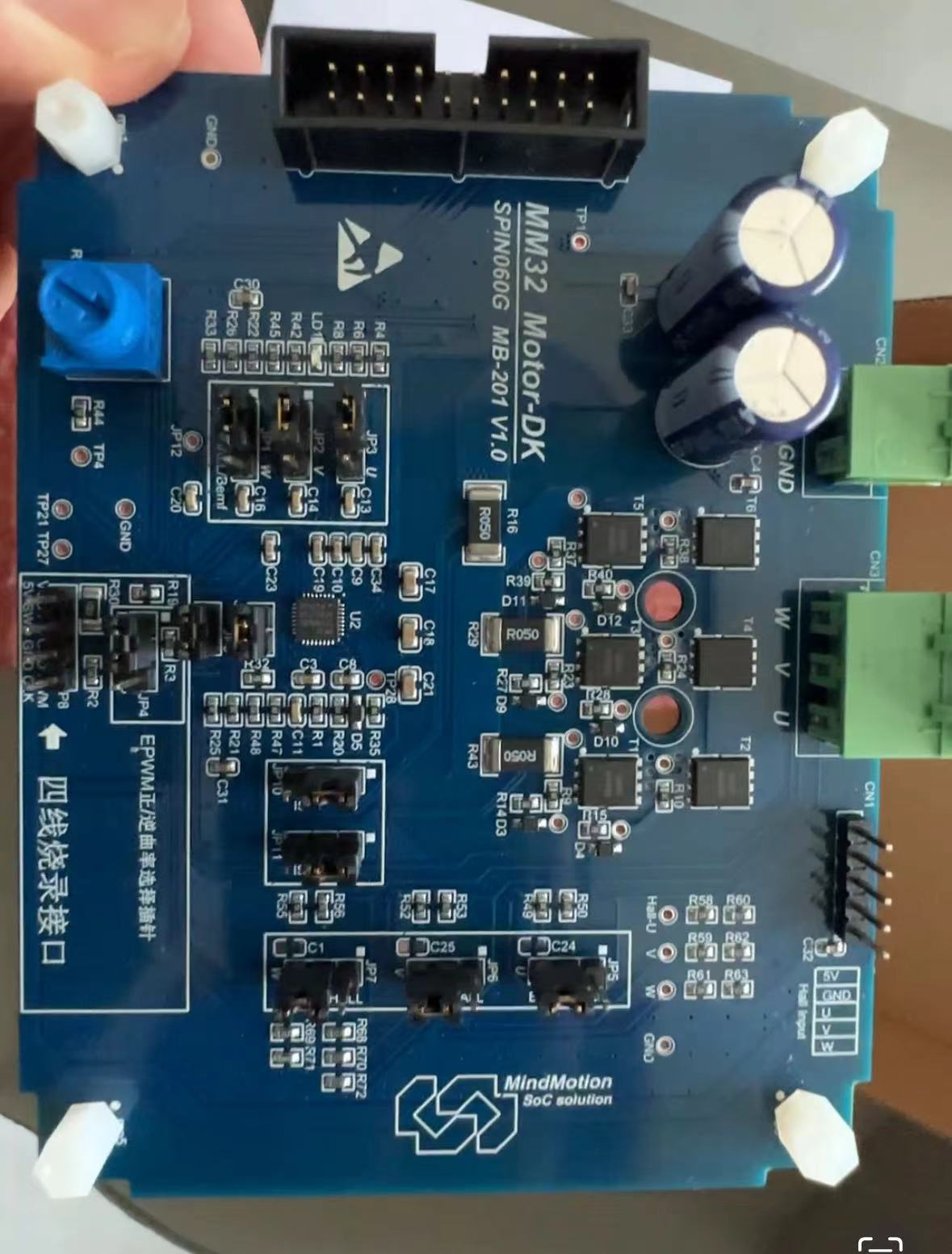

二、简单开箱+介绍

板子硬件上包含有

1.直流电源输入,其范围在5.5~18V

2.UVW三相电压

3.霍尔接口

4.电位器

5.烧录调试接口

6.反电动势或者霍尔跳线接口

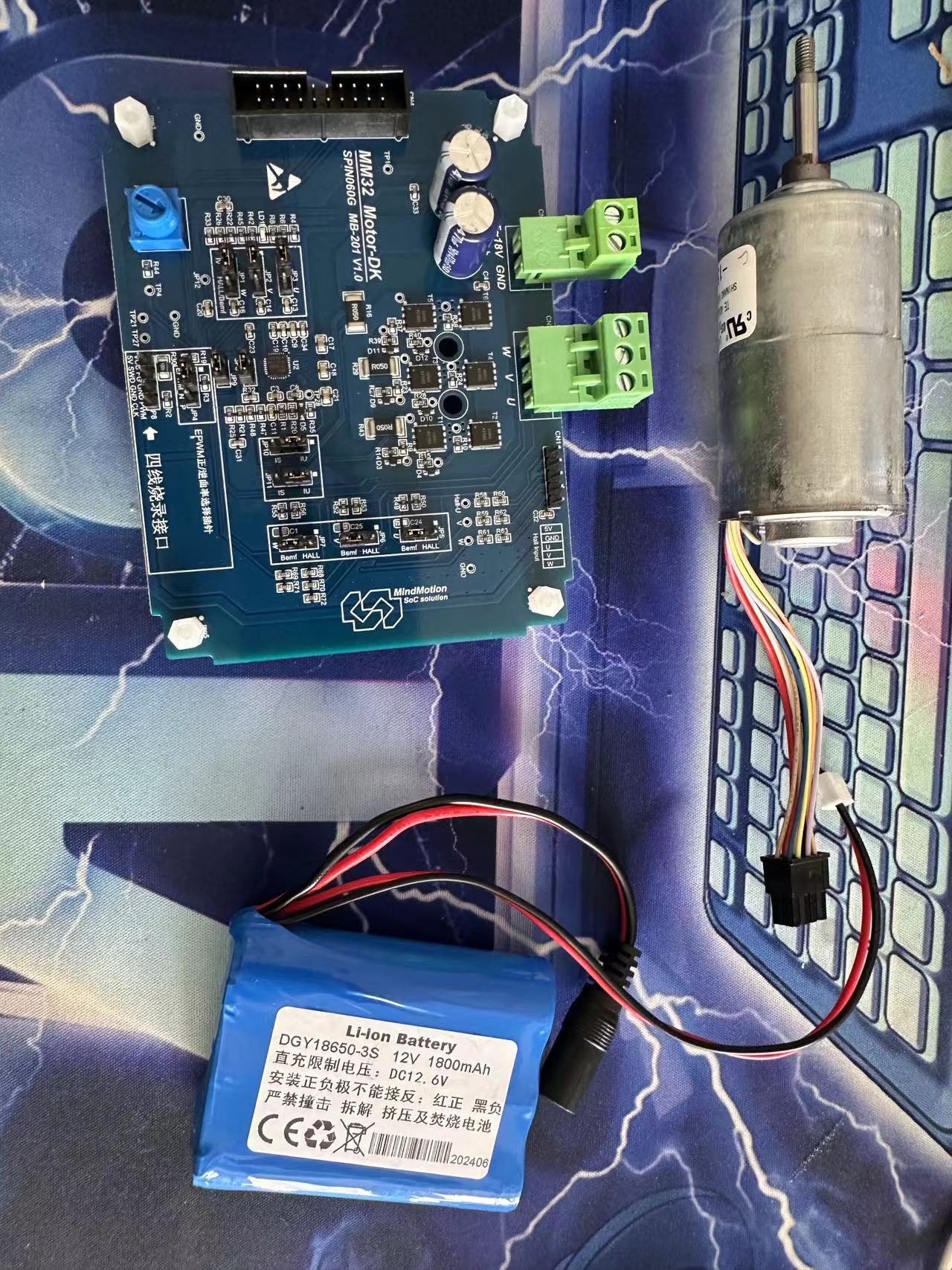

三、测评所用到的硬件

MM32SPIN060G、12V电源、无刷电机(DC105)

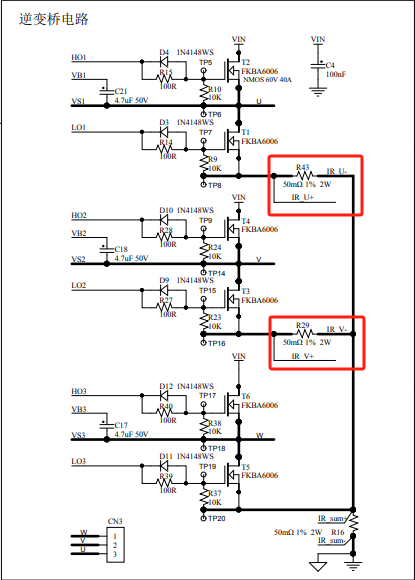

四、双电阻采样-无感FOC

1.双电阻采样电路,选择插针,采集U相、V相电流,通过三项电流之和为零的原理计算出W相电流。

2.无位置传感器控制

通过矢量控制的介绍可知转子位置信息对矢量控制至关重要,PMSM 的转子位 置信息可以通过专用的位置传感器,例如光电编码器、磁编码器、测速发电机或 者开关霍尔等传感器获取。速度传感器会给电机带来额外的硬件成本和维护成本, 因此近些年无位置传感器控制应用越来越广泛。目前主流的无位置传感器算法包 括滑模观测器、反电势观测器、磁链观测器、卡尔曼滤波器、模型参考自适应观 测器等算法,本应用使用了滑模观测器法来实时观测转子位置。 滑模控制应用于转子位置估算中位置较准确,对控制对象的参数变化及扰动具有 自适应能力,而且该方案实现简单,对 MCU 资源没有太大要求。

五、官方代码大致介绍

ADC采样 ,通过定时器触发方式,

void Bsp_Adc_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_StructInit(&GPIO_InitStructure);

/* ADC Clock Enable */

RCC_AHBPeriphClockCmd(ADC_GPIO_CLK, ENABLE);

/*Condiv ADC pin */

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AIN;

GPIO_InitStructure.GPIO_Pin = VR_PIN;//调速

GPIO_Init(VR_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = VBUS_PIN;//电压

GPIO_Init(VBUS_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = IR_V_PIN;//V相电流

GPIO_Init(IR_V_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = IR_U_PIN;//U相电流

GPIO_Init(IR_U_PORT, &GPIO_InitStructure);

}

void Board_ADC_Init(void)

{

/*ADC RANK Array*/

ADC_Channel_TypeDef sUserAdc1Channel[4];

/* Condiv the ADC RANK Sequence*/

sUserAdc1Channel[0].u8Rank = IR_U_RANK;

sUserAdc1Channel[0].sAdcChannel = IR_U_CHANNEL;

sUserAdc1Channel[0].pNext = &sUserAdc1Channel[1];

sUserAdc1Channel[1].u8Rank = IR_V_RANK;

sUserAdc1Channel[1].sAdcChannel = IR_V_CHANNEL;

sUserAdc1Channel[1].pNext = &sUserAdc1Channel[2];

sUserAdc1Channel[2].u8Rank = VBUS_RANK;

sUserAdc1Channel[2].sAdcChannel = VBUS_CHANNEL;

sUserAdc1Channel[2].pNext = &sUserAdc1Channel[3];

sUserAdc1Channel[3].u8Rank = VR_RANK;

sUserAdc1Channel[3].sAdcChannel = VR_CHANNEL;

sUserAdc1Channel[3].pNext = NULL;

/* Select the ADC external trigger source of the ADC is T1_CC4*/

Drv_Adc_Basic_Init(ADC1, ADC_ExtTrig_T1_CC4);

/* Select the ADC sample time*/

Drv_Adc_Channel_Init(ADC1, sUserAdc1Channel, ADC_SampleTime_2_5);

}

比较器

void Bsp_Comp_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_StructInit(&GPIO_InitStructure);

/* COMP Clock Enable */

RCC_AHBPeriphClockCmd((COMP_GPIO_CLK), ENABLE);

GPIO_InitStructure.GPIO_Pin = COMP_INP_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AIN;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_High;

GPIO_Init(COMP_INP_PORT, &GPIO_InitStructure);

}

void Board_Comp_Init(void)

{

COMP_Input_TypeDef sUserCompInput;

/* Select the inverting input of the comparator */

sUserCompInput.sCompInvertingInput = COMP_INVERTING;

/* Select the non inverting input of the comparator*/

sUserCompInput.sCompNonInvertingInput = COMP_NON_INVERTING;

/* Select comparator external reference voltage */

sUserCompInput.u8CompCrvSelect = COMP_CRV_VOLTAGE_SELECT;

/* Initializes the COMP according to the specified parameters in the COMP_Input_TypeDef */

Drv_Comp_Init(COMP_NUMBER,&sUserCompInput);

}

六路PWM初始化

void Bsp_Pwm_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_StructInit(&GPIO_InitStructure);

/* PWM Clock Enable */

RCC_AHBPeriphClockCmd(BLDC1_GPIO_CLK, ENABLE);

/*Condiv GPIO pin : PWM_Pin */

GPIO_InitStructure.GPIO_Pin = BLDC1_UH_PIN;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_High;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP;

GPIO_Init(BLDC1_UH_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BLDC1_VH_PIN;

GPIO_Init(BLDC1_VH_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BLDC1_WH_PIN;

GPIO_Init(BLDC1_WH_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BLDC1_UL_PIN;

GPIO_Init(BLDC1_UL_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BLDC1_VL_PIN;

GPIO_Init(BLDC1_VL_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = BLDC1_WL_PIN;

GPIO_Init(BLDC1_WL_PORT, &GPIO_InitStructure);

/*selects the pin to used as Alternate function of PWM*/

/*六个IO口,六个桥臂 UVW三个上桥 UVW三个下桥*/

GPIO_PinAFConfig(BLDC1_UH_PORT, BLDC1_UH_PIN_SRC, BLDC1_UH_PIN_AF);

GPIO_PinAFConfig(BLDC1_VH_PORT, BLDC1_VH_PIN_SRC, BLDC1_VH_PIN_AF);

GPIO_PinAFConfig(BLDC1_WH_PORT, BLDC1_WH_PIN_SRC, BLDC1_WH_PIN_AF);

GPIO_PinAFConfig(BLDC1_UL_PORT, BLDC1_UL_PIN_SRC, BLDC1_UL_PIN_AF);

GPIO_PinAFConfig(BLDC1_VL_PORT, BLDC1_VL_PIN_SRC, BLDC1_VL_PIN_AF);

GPIO_PinAFConfig(BLDC1_WL_PORT, BLDC1_WL_PIN_SRC, BLDC1_WL_PIN_AF);

GPIO_InitStructure.GPIO_Pin = GPIO_Pin_3;

GPIO_InitStructure.GPIO_Speed = GPIO_Speed_High;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_Out_PP;

GPIO_Init(GPIOB, &GPIO_InitStructure);

GPIO_SetBits(GPIOB, GPIO_Pin_3);

}

void Drv_Pwm_Init(TIM_TypeDef * pTim, uint16_t u16Period,uint16_t u16DeadTime)

{

/** Define the struct of the PWM configuration */

TIM_TimeBaseInitTypeDef TIM_TimeBaseStructure;

TIM_BDTRInitTypeDef TIM_BDTRInitStruct;

TIM_OCInitTypeDef TIM_OCInitStructure;

/** Enable the TIM1 clock */

RCC_APB1PeriphClockCmd(RCC_APB1ENR_TIM1_Msk, ENABLE);

/**

* Sets the value of the automatic reload register Period for the next update event load activity

* Set the Prescaler value used as the divisor of the TIMx clock frequency

* Set clock split :TDTS = TIM_CKD_DIV1

* TIM center aligned mode1

*/

TIM_TimeBaseStructure.TIM_Period = u16Period;

TIM_TimeBaseStructure.TIM_Prescaler = 0;

TIM_TimeBaseStructure.TIM_ClockDivision = 0;

TIM_TimeBaseStructure.TIM_CounterMode = TIM_CounterMode_CenterAligned2;

TIM_TimeBaseStructure.TIM_RepetitionCounter = 0;

TIM_TimeBaseInit(pTim, &TIM_TimeBaseStructure);

/**

* Enable state selection in running mode

* Enable state selection in idle mode

* Software error lock configuration: lock closed without protection

* DTG[7:0] dead zone generator configuration (dead zone time DT)

*/

/**

* TDTS = 125nS(8MHz)

* DTG[7: 5] = 0xx => DT = DTG[7: 0] * Tdtg, Tdtg = TDTS;

* DTG[7: 5] = 10x => DT =(64+DTG[5: 0]) * Tdtg, Tdtg = 2 * TDTS;

* DTG[7: 5] = 110 => DT =(32+DTG[4: 0]) * Tdtg, Tdtg = 8 * TDTS;

* DTG[7: 5] = 111=> DT =(32 + DTG[4: 0]) * Tdtg, Tdtg = 16 * TDTS;

*/

TIM_BDTRInitStruct.TIM_OSSRState = TIM_OSSRState_Enable;

TIM_BDTRInitStruct.TIM_OSSIState = TIM_OSSIState_Enable;

TIM_BDTRInitStruct.TIM_LOCKLevel = TIM_LOCKLevel_OFF;

TIM_BDTRInitStruct.TIM_DeadTime = u16DeadTime;

/**

* Brake configuration: enable brake

* Brake input polarity: active in low level

* Auto output enable configuration: Disable MOE bit hardware control

*/

TIM_BDTRInitStruct.TIM_Break = TIM_Break_Enable;

TIM_BDTRInitStruct.TIM_BreakPolarity = TIM_BreakPolarity_High;

TIM_BDTRInitStruct.TIM_AutomaticOutput = TIM_AutomaticOutput_Disable;

TIM_BDTRConfig(pTim, &TIM_BDTRInitStruct);

TIM_BreakInputFilterConfig(pTim,TIM_COMPBKIN_COMP2,TIM_BKINF_2);

TIM_BreakInputFilterCmd(pTim, ENABLE);

/**

* Mode configuration: PWM mode 1

* Output status setting: enabl0Ce output

* Complementary channel output status setting: enable output

* Sets the pulse value to be loaded into the capture comparison register

* Output polarity is high

* N Output polarity is high

*/

TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM2;

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable;

TIM_OCInitStructure.TIM_OutputNState = TIM_OutputNState_Enable;

TIM_OCInitStructure.TIM_Pulse = 0;

TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High;

TIM_OCInitStructure.TIM_OCNPolarity = TIM_OCNPolarity_High;

TIM_OCInitStructure.TIM_OCIdleState = TIM_OCIdleState_Reset;

TIM_OCInitStructure.TIM_OCNIdleState = TIM_OCNIdleState_Reset;

TIM_OC1Init(pTim, &TIM_OCInitStructure);

TIM_OC2Init(pTim, &TIM_OCInitStructure);

TIM_OC3Init(pTim, &TIM_OCInitStructure);

/** Initialize the CCR4 trigger point */

TIM_OCInitStructure.TIM_Pulse = 10;

TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Disable;

TIM_OCInitStructure.TIM_OutputNState = TIM_OutputNState_Disable;

TIM_OC4Init(pTim, &TIM_OCInitStructure);

/** Enable CH1, 2, and 3 to be preloaded */

TIM_OC1PreloadConfig(pTim, TIM_OCPreload_Enable);

TIM_OC2PreloadConfig(pTim, TIM_OCPreload_Enable);

TIM_OC3PreloadConfig(pTim, TIM_OCPreload_Enable);

/** Enable TIMx's preloaded register on ARR */

TIM_ARRPreloadConfig(pTim, ENABLE);

/** Enable the TIM1 */

TIM_Cmd(pTim, ENABLE);

/** Main Output Enable:Disable the MOE bit */

TIM_CtrlPWMOutputs(pTim, DISABLE);

}

运算放大器初始化

void Bsp_Op_Init(void)

{

GPIO_InitTypeDef GPIO_InitStructure;

GPIO_StructInit(&GPIO_InitStructure);

/* GPIO Ports Clock Enable */

RCC_AHBPeriphClockCmd(OPAMP_GPIO_CLK, ENABLE);

/*Condiv GPIO pin : OPAMP1_Pin */

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AIN;

GPIO_InitStructure.GPIO_Pin = OPAMP1_INM_PIN;

GPIO_Init(OPAMP1_INM_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = OPAMP1_INP_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AIN;

GPIO_Init(OPAMP1_INP_PORT, &GPIO_InitStructure);

/*Condiv GPIO pin : OPAMP2_Pin */

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AIN;

GPIO_InitStructure.GPIO_Pin = OPAMP2_INM_PIN;

GPIO_Init(OPAMP2_INM_PORT, &GPIO_InitStructure);

GPIO_InitStructure.GPIO_Pin = OPAMP2_INP_PIN;

GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AIN;

GPIO_Init(OPAMP2_INP_PORT, &GPIO_InitStructure);

}

void Board_Opamp_Init(void)

{

/* op-amp Clock Enable */

RCC_APB1PeriphClockCmd(RCC_APB1ENR_OPA1_Msk, ENABLE);

RCC_APB1PeriphClockCmd(RCC_APB1ENR_OPA2_Msk, ENABLE);

/*Enable the specified OPAMP peripheral*/

OPAMP_Cmd(OPAMP1,ENABLE);

OPAMP_Cmd(OPAMP2,ENABLE);

}

主函数

int main(void)

{

/* Condiv the system clock */

Systick_Init(SystemCoreClock / 1000);

Systick_Delay(200);

/* 初始化电机控制参数 */

Init_Parameter(&Motor_1st);

/* 初始化所有GPIO */

Bsp_Gpio_Init();

/* 初始化所有已配置的外围设备 */

Peripheral_Init();

/* 初始化中断*/

Interrupt_Init();

while(1)

{

/*IWDG_ReloadCounter*/

IWDG_RELOAD_COUNT();

if(Motor_1st.USER.bSlowLoopFlag)

{

/* Slow Loop Statemachine */

s_STATE_SLOW[eM1_MainState]();

Motor_1st.USER.bSlowLoopFlag = 0;

}

}

}

这里看门狗防止系统出现问题跑飞,下面的if是通过状态机进行电机的控制。

大致解释一下,状态机的执行过程。首先Motor_1st.USER.bSlowLoopFlag 为真(此历程提供了低速循环和高速循环,这里使用的是低速循环),则通过 s_STATE_SLOW[eM1_MainState]() 调用执行当前状态对应的函数。其中s_STATE_SLOW 是一个包含四个函数指针的数组,这些函数指针分别指向 M1_Fault_Slow、M1_Init_Slow、M1_Stop_Slow 和 M1_Run_Slow 四个函数。eM1_MainState 是一个枚举变量( MainState_Fault = 0, MainState_Init = 1,MainState_Stop = 2, MainState_Run = 3,),它决定了从 s_STATE_SLOW 数组中选择哪个函数指针进行调用。进而完成电机的启动过程。

六、事物演示

全部评论